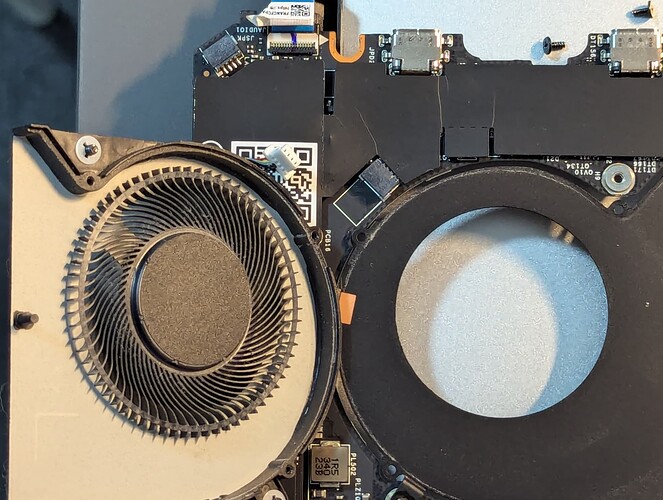

It’s right above the fan, there is literally a halo of dust around the hole.

peeling off the sticker requires significant force. I don’t want to damage the fan. Anyway here’s what near the wire. Here are P - F +, which probably means PWM, GND, frequently, voltage source

Other components are likely to be under the PCB

Seems to match the color coding, blue tends to be pwm and yellow tach, red and black probably don’t need much thinking.

But this isn’t the same fan as the order of the wires is different. On the burned one it’s blue, red, yellow, black.

According to the controllers datasheet it needs 2 capacitors, 1 small one close t the controller and a bigger one to temporarily store the power coming back from the coils, if that one was in that area it would probably be it. That capacitor is probably the thing with the most stress on it on that whole board.

Asking proton to autopsy the fan is probably asking too much here XD.

I just had the same failure on my first gen (i5-1135G7) Framework.

I’m just minding my own business, soldering together a weird keyboard at my computer desk…I hear a clicking noise from my right, which is weird because there shouldn’t be anything over there making noise. I look up and there’s smoke – for a moment, I think “is that from my soldering iron?” but then I realize it’s way too much smoke and it’s in the wrong place!

My next thought is that I’ve got a lithium battery fire on my hands, so I run around my desk, unplug the laptop from the dock, and run down the steps and out the front gate in my socks. I notice during this process that the laptop does not seem to be actively on fire…eventually I am able to get my tools and unscrew the bottom of the laptop. I open up the computer to lift off the input cover and find the computer is still on! Good indication that the battery has not failed.

The damage is not immediately obvious, but I eventually notice the burn marks on the fan.

Phew, that freaked me out. I think I caught it much earlier than u/proton1, because there’s much less damage.

That’s a little worryingly to me. I thought my fan failure might just be a one-off issue. But from the photos it does seem that we experienced the exact same problem, with mine unfortunately having a longer exposure.

Did replacing the heatsink and fan resolved your issue?

That is eerily in the same location as the other one, I wish I knew what’s under there.

Could be the big cap for the motor driver but it’s hard to tell, very unlikely that it’s just a random bit of the pcb that decided to blow itself up in the same spot on 2 fans.

I am assuming in your case the motor driver still looks fine and there isn’t any discoloration near it right?

Since the fans are dead anyway can one of you autopsy one? Would love to see that pcb without the plastic.

The failure happened just an hour before my post, so I haven’t had a chance to repair yet. I don’t anticipate it being a problem given the laptop was still functioning partway through disassembly. Might take the opportunity to switch to PTM7950, hopefully this will resolve some of the excessive fan noise I’ve been having.

I don’t expect Framework to revise this component so far after the production date, there’s just no way that’ll make sense economically. I might disassemble the fan out of curiosity, though.

Replacing the HSF was as easy as replacing a desktop HSF. Easier even, since I didn’t have to apply paste myself (didn’t bother with PTM7950). I’m impressed.

I partially disassembled the HSF, but I can’t find a good way to separate the shroud from the controller PCB. I’m not planning to investigate further, but if someone wants the failed fan I’m willing to ship it.

Glad to hear replacing the component went smooth and easily. If there was more widespread failures like this it would be worthy of looking further. Such a simple mechanism and relatively inexpensive to replace.

The fan is probably unique that might be the reason it’s not independent of the heat sink. There’s a way of cleaning dust without repasting. Unscrew two screws on the fan from the mainboard then go to the back side and unscrew there smaller screws, open up this way to avoid removing the (very tiny) duck tape.

buy an apple sticker, slap it on and turn it into a macbook, this laptops passive performance is leaps and bounds ahead of a 50 degree c lap ![]()

You’re not alone! I ordered 6 of the 11th Gen Factory Seconds for our school and one so far has shown this exact issue with a few others starting to have fan buzzing issues which I can only assume will end up like this as well. What’s worse is the one that had the fan burn up starting emitting smoke and had the classic burnt electronics smell. It was sitting idle at the time with no one in the classroom. Luckily one of the students smelled the burning and saw the smoke.

I’ve already opened a ticket with Framework for that particular unit and they’re sending me both a replacement fan assembly and mainboard. That said I’ve seen other folks report fan issues with the 11th Gen and replacing the fan assembly only results in the same issue cropping back up. I’m honestly hesitant to redeploy the unit even after replacing the apparent problem components. ![]()

It looks like what would happen if some conductive dust of other thing went under the sticker and shorted two adjacent wires by bridging the solder pads.

On the other hand, the burn mark seems to stretch far from the wires’ solder pad on the right side.

If the fan is melting then there is a problem with the fan’s own motor control circuit. So if a new fan has that problem fixed, replacing the fan could be a good fix.

Now it could be said that maybe the FW13 mainboard could have had implemented some overcurrent protection to at least result in a fan failed log message. It would make for less smoke.

I have generally found, that cheap devices tend to have less protection components than more expensive devices.

E.g. there are ways to protect triacs, but very few devices I have seen from China have any triac protection. Resulting in devices that fail quite often.

There will always be a certain percentage of fans fail, it is commonly referred to as MTBF - Mean Time Before Failure. The figure is generally applied to disk drives where the item is in continuous use (e.g servers), but it applies to all items. Problem is that a considerable number of units need to be tested to arrive at the figure.

Bu the other statistical tool for failures is the bathtub curve. That wikipedia article explains it pretty well, and also shows you will always get failures at all ages of the equipment.

Thank you for sharing. I just had the same issue. This is my second fan. First one still works but is too noisy.

Laptop was off for a month or so and after turning it on today I noticed it was too quite and overheating.

Fan wasn’t spinning

It also damaged the keyboard a bit

Moving the black cable a bit revealed it is off.

For the people seeing fans failing like the above. Do any of you know what sort of humidity level do you have?

Is it high or low?

I cannot find any specifications for the FW13 or FW16 that state its operating humidity range, but thought it might give a clue as to why the fans are failing.

I only thought of this because recently, an old display monitor failed, with a puff of smoke, and my analysis of the cause was condensation. Fractal burning of PCBs is not as pretty as on wood, but just as dangerous. I have purchased a humidifier now, to prevent any more of my electrical equipment from joining in on the fun. ![]()

It turned out its operating humidity range was 10 to 70%, and it was hovering around 74% at the time.

Not a humidity issue ![]()

Someone please autopsy one, my curiosity is killing me here.

Same, and why always the black cable