Thanks man for peeping the thread. I know its outside your scope. But we do appreciate your communication in the forums!!!

ok so unless you had your rma replacement november onwards you probably still have LM?

That’s what its seems like and makes most sense per the announcement.

I believe so.

Is there an eta for the guide on replacing the LM with PTM? I have my own PTM and bought an extra heat sink, but am hyper-paranoid about the LM and nuking my board. Hoping to wait for the official guide rather than winging it.

Thanks!

this is the knowledgebase article: Phase Change Thermal Pad Kit Request form

Thanks for the reply. I have seen that and applied to have the replacement material sent to me when it is available.

What I was intending to ask is if there will be a step by step guide produced for doing the swap, particularly regarding safely removing the liquid metal, which iirc as formulated here is solid at normal room temps. I am concerned about scraping it off, missing some, somehow spilling some unbeknownst to me on the board. I could farm the work out, but if there is at least an official process I will feel better about doing it myself vs winging it when doing it myself.

Thanks again, and have a great weekend!

Yes, there should be a detailed guide, however (as far as I know) we haven’t published it yet.

Can’t believe its only been a few weeks and the RMA board is going bad already.

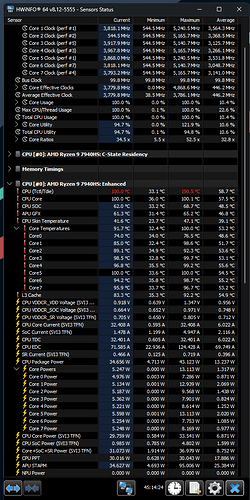

27c difference between core 5 and 0, maxes out at 35W and dropped from 15.6k Cinebench to 13.7k

Yup! It’s a fundamental design flaw so RMA is useless you will get another board with the same issue. I put my RMA on hold until the new boards are released with PTM7958.

For Linux, you can find information out about the board:

dmidecode

…

Handle 0x0002, DMI type 2, 15 bytes

Base Board Information

Manufacturer: Framework

Product Name: FRANMZCP07

Version: A7

Maybe the boards with PTM might have an different Version number?

What do other people find. Is everyone A7 ?

My one is a Batch 16 FW16.

Handle 0x0002, DMI type 2, 15 bytes

Base Board Information

Manufacturer: Framework

Product Name: FRANMZCP09

Version: A9

Serial Number: <redacted>

Asset Tag: *

Features:

Board is a hosting board

Board is replaceable

Location In Chassis: *

Chassis Handle: 0x0003

Type: Motherboard

Contained Object Handles: 0

![]()

![]()

![]()

![]()

So that is going to be the next production batch which will occur at some time in the future from that date. When that will be is anyones guess, but I cannot see machines currently in stock being dismantled for rework.

I have been reading the specs of PTM7950.

It mentions “30~40 psi pressure is needed for usage”

How does one ensure the correct pressure?

Math.

Intuitively, though, that’s not actually all that much and I’m sure the heat sink is perfectly capable of applying that pressure. I wouldn’t worry about it.

The heat sink mounting screws are set in arms that end up applying the pressure. Without that pressure, pretty much no laptop heat sink would work well.

You don’t need to worry about the correct pressure unless you’re designing a whole heat sink and mounting replacement.

1 psi is about 6.895 kPa 1 kPa is 1000N/m^2 the 7840/7940HS had 178 mm^2 which is 0.000178m^2.

1.22731N/0.000178m^2=6895Pa=1psi, so you need about 42N on the heat sink for the PTM to work properly

That is what I was trying to get at. If the PTM needs 30-40psi, we are going to need torque screwdrivers in order to get the PTM replacement done correctly.

I think you are overthinking it.

Just tighten the heatsink down as far as it will safely go… dont over-tighten it and snap off the screws… just tighten it down snug - same as you would for any other paste.

The torque settings are more for industrial server applications (what PTM7950 was designed for)

Funny Thing, i closed the Vents of the dGPU today, with black Vinyl. i only left open two of the Squares of each Vent.

I wanted to check how it increases the Pressure and Airspeed through the CPU Cooling Vents, Effectivly it reduces the Noise of the Device alot and keeps the Cpu a teenie tiny bit cooler.

I will leave the Vents closed for my stationary Work with my eGPU and just open them if i am traveling and i need the dGPU.