That won’t make upwards facing leds look much different in that case. No amount of sanding is gonna smooth out those intensity differences.

Should still be an improvement and an easy stop-gap at least.

Would not be that sure, sanding 3d prints can have weird results. Often it looks quite a lot worse till it looks better. Enabling ironing fir the top layer would have probably been the better move here.

Ironing would smooth it out too much, I’d think. The goal would be to make the surfaces rougher so the light can’t take a straight path through the material. Doing both the ironing and sanding could work so that you don’t have so much sanding to do.

Or you could use a diffuser that’s literally made for that purpose XD

How about trying white filament instead? Will still have hot spots, but it won’t be too bright.

It looks really cool! Have you considered using something like sandpaper on the 3D printed logo to diffuse the light?

Great work Luke; as others have suggested take some 800 or 400 grit sandpaper and wetsand (just get the paper wet is all you would need to do) the underside of the logo closest to the LEDs. Between 400 and 800 grit should get a nice matte look to diffuse the light. The LEDs are probably too bright overall to be super uniform.

Other thoughts:

-

You could also experiment with piece(s) of wax paper between the logo and the LEDs to get it a little more opaque.

-

If you are really feeling creative, try putting a little bit of cotton in the holes to dim the light and diffuse the light coming from the LEDs a little.

-

If Framework offered this as an optional cover in the Marketplace like the bezels I would buy it for sure.

-

Future iterations of it could dimly show the battery remaining while the laptop is in sleep mode like a clockface (100% all dim and glowing super slow; 75% 1-3 o’clock dark; 50% 1-6 o’clock dark, etc.)

A couple minor updates:

I’m back on campus, and the first week has been hectic, so I haven’t accomplished much. The machine shops are closed until next week, so I don’t have access to sandpaper quite yet (I tried sanding at home, but all we had was 100 grit, and it didn’t work super well). I also re-printed the logo as almost entirely walls and no infill, which changes the appearance pretty significantly, and I actually like it a lot better that way.

I did try cotton, but I couldn’t get it to sit in the holes very well, and it came through rather splotchy. I did end up disassembling that old LCD I had and yanking the diffusion layer, as well as two semi-mirrored sheets of something. Messing with those I can get pretty good diffusion, so I may cut them into fromework-logo shaped pieces and try and put them underneath the 3D printed piece.

I went to the EE lab today to try and find 5V I can yank, and it’s going to be harder than I thought. The fingerprint reader definitely uses 5V and some kind of control to change its light, but the signal is either more complicated than I can parse in the pins (there are 3 of them, a W, R, and G signal, and I couldn’t figure out what they were doing, I don’t have perfectly stable fingers or a 3-channel oscilloscope). It may be doing the dimming internally, because with the laptop asleep, I couldn’t read any change in the signals when the fingerprint reader was flashing. I think I could get into the sensor and take power directly from the LED’s on the board, because it is at 5V, I would be effectively just adding a bunch of them in parallel. The PCB for the fingerprint sensor is plastic-welded in the casing though, and I don’t have an extra one of those at the moment to try and disassemble, which I’m not even sure would work. The lights flickered really bad with 3.3v, so that isn’t really an option unless I redesign it to use different lights or smaller resistors or something, and if I’m resetting to change the design I’d end up changing just about everything.

The backlight for the display uses 5-21V, according to the pinout, but I didn’t want to pry into the screen at risk of damaging something; that isn’t a cheap part.

This is a really cool idea, but definitely a few steps above my paygrade. I did consider using a dedicated expansion card with some kind of USB RGB controller that I could wire up to the lights, but that would take an entire slot, and getting a controller that small seems like it would be difficult.

They also make sk9822 based 5v RGBW, so with white in addition to RGB. It’s a thought. Probably would need to use a ATtiny85 or something, and talk to it over SPI or UART. Which you’d then need a USB hub chip to put on the USB lines to the webcam or something.

Or something with a Bluetooth, so you can pair the 2 together. an ESP8266 may not be quite small enough, but something to think about.

If you’re interested in exploring options, I could offer one.

Since space is limited, rather than some purpose made RGB controller, you could go for just a general purpose microcontroller. The RP2040 is used in the FWL16 keyboard and other input modules. It’s not the smallest possible option, but it’s easy to use, and still might be small enough to stick somewhere without needing to take up an expansion card slot.

Here is a 20mm x 18mm x 3mm high RP2040 board aliexpress.us/item/3256805628494981.html

I don’t know much about RGB controller firmware, but openRGB would probably work. Someone made an QMK openRGB port for the FWL16 keyboard. I tried flashing it to a spare RP2040 board I have and it loaded up ok at least.

For the RGB LEDs themselves, I’d use some WS2812B compatible LEDs. They will only need 3 wires, power 5v positive, negative, and 1 data wire from the microcontroller. The LEDs come as small as 1.4mm x 1.4mm. And jlcpcb has them, so you could get a board assembled. jlcpcb.com/partdetail/OpscoOptoelectronics-SK6805EC14/C2909055. You can also get them on a strip for just testing out how they work, if you’ve never used them before. A 2.7mm wide WS2812B LED strip aliexpress.us/item/3256806542970058.html

Is there an update for this? Just got my FW13 and stumbled across this post and found it super interesting!

I remember that - testing for the extent of liquid damage when there was nothing on the display. Shine a torch through the Apple logo on the back, et viola…the voltage controller for the backlight was usually the first thing to short.

It’s been far too long of me just sitting on the parts and not finishing this project, but I want to get it done.

I’ve got a lot more experience now with surface-mounting components and soldering those kinds of things myself, and I figured out both what the problem was and what I need to do about it.

The LED’s strobed pretty bad with less than 4V input, and I figured out that it was because the resistors I was using were too large, so the current was too low. I did some math and ordered resistors that will be the right size (660 ohm vs 1k), so I’ll replace those on the boards I already have once those arrive.

I never did update this thread with the progress I saw from sanding the logos or using the old LCD diffusers, but I did try it. I didn’t take any photos at the time, but in short, they both helped a little bit, but didn’t make a huge difference. The LCD diffusers were rather thick, and difficult to keep where I needed them, so going forwards I’ll definitely just use a single 3D-printed part that I’ll probably end up gluing into the spot.

I have, since the last update, bought myself a Bambu Lab A1 Mini, so I may be able to do something cool with multi-color printing to help with the diffusion (I’m thinking 3 really thin layers, white, then clear, then white again), and I have a 0.2mm nozzle that I can use to get a much finer detail part.

I looked at maybe getting the old PCB I designed manufactured as a flex PCB, so it would fit in the chassis easier, but I didn’t realize the costs for that were so much more expensive (like $140 for them to assemble the same components on a flex PCB). If I put together the system with the 2mm PCBs that I have and they’re too thick, I may order flex PCBs and build them myself, but having JLC do the surface mounting is simply out of my price range.

I ordered some 36 awg wire to hopefully get into the tiny spaces I need to pull power from. I’m going to try and pull 3V3 from the webcam module if I can, but if the connections there are too difficult, or that doesn’t work, I can probably just yank it off of the motherboard somewhere and run those wires through the wire wrap that’s already going through the hinges.

I should have those parts in hand and some real progress in the next week or two, which is exciting. I hate to have cool projects like this stagnating in my backlog, so I’m going to finally finish this one out.

It is pricy, and I’m not sure how you would get the 180-200V required, but there is a product that you can paint on and light up: https://www.lumilor.com/

I think you should keep going on this path, but maybe someone else might want to give this stuff a try.

Major Update: I did it!! ![]()

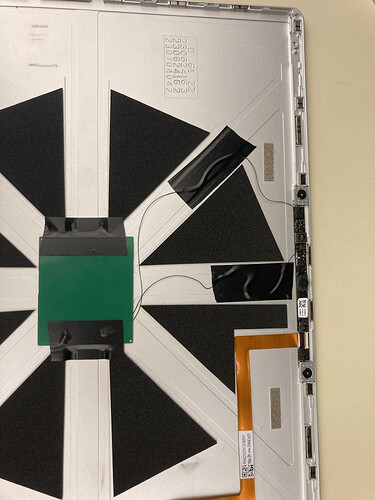

I finally bit the bullet last week and put together the new top case with my PCB, as well as tapping into the webcam’s 3V3 supply with 36 AWG wire that I ordered, and it works amazing! Photos to follow:

The parts are genuinely affixed with Electrical Tape. I worried about gluing them in and messing things up somehow, so I figured I would try taping them and make sure it worked before doing anything permanent, but the back of the display holds the PCB in place well enough with just the tape there that I don’t think I will need to glue it. It has only been a few days, so things could still change, but it doesn’t seem like the internals have moved at all. The PCB is almost exactly the thickness of the foam that’s built into the top case, so it actually fits perfectly into the chassis. I only had to cut out a few mm of foam in one spot, and I just did that with a pocket knife.

I was able to snag 3V3 and GND from the webcam module relatively easily. The large pads on the edges for grounding the chassis were ground pads, so I could just solder to one of them, and I found the 3V3 line on one of the pins of the (relatively) large transistor you can see in the fourth image above. I had to wrap the wire around the back of the webcam, but that worked just fine.

The resistors I mentioned possibly needing to switch out in my last post turned out to be unnecessary, because the boards worked just fine on 3.3V. I suspect the power supply I used to test them at 3V3 way back when was unreliable, because I was using a LIPO battery charger in a special mode, not an actual benchtop power supply.

I went through a few revisions of 3D-printed inserts to use before deciding on a cool multicolor swirl design. Orange is my favorite color, so I made the logo orange and white. This piece is glued in with just a tiny dab of superglue on each of the “points” of the logo, but I have acetone and could probably switch it out if the logo gets damaged or something.

It’s imperfect (the little orange line in the one white section does bug me, but if the lights are on or you’re at a reasonable distance it isn’t noticeable), and the blue coloring in the 2nd photo is a factor of the white balance of the camera in my relatively warm-lit room, to the human eye it’s a pretty pure white color.

It does stay lit when the laptop is asleep, which I didn’t expect, but is okay with me. I only very rarely leave my laptop asleep rather than hibernating or shut down, so it actually brings me some peace of mind that it is fully off, when before I would have some battery anxiety over whether it was asleep or shut down.

I wish I had been more careful when removing the original logo and drilling the holes, because there’s a good bit of scuffing around the logo, but once I start adding stickers to this top case it will quickly become nearly unnoticeable.

I am more than happy to share the files and designs I used for this if anyone wants to follow in my footsteps, the hardest part is drilling the holes in the top case and soldering to the webcam, but if you have access to the tools and want to recreate this, I think it’s entirely doable by someone that’s inexperienced. I drug the process out over nearly a year ![]() , but if you have all the parts and some motivation, you could probably get it all done in one good saturday.

, but if you have all the parts and some motivation, you could probably get it all done in one good saturday.

I’m somewhat interested in some kind of guide on how to create this. I’m thinking of updating my ancient OG batch 2 mainboard soon and adding a glowing logo while I’m at it might be fun.