Hey y’all ![]()

So I bought the Honeywell PTM7950 Phase Change Thermal Pads/Sheets (from both ebuy7 and aliexpress) and it took 2 weeks to arrive from China. I’m not sure if I can post the link, so I’ll post it as a thread reply if someone asks. Mods please delete/let me know if necessary!

EDIT

I added links, and it seems that I received different products from aliexpress vs. ebuy7. The write-up below is for the aliexpress link which is 0.2mm. I just took the ebuy7 package from my mail and opened it up. That version looks slightly more blue (turns out the material is the same color, just the plastic film has a blue tint), feels slightly thicker, and the box says 0.25mm.

I looked around the internet and it seems that many users have been using the 0.2mm version?

So I’m not sure if I received a fake product. This Honeywell product sheet says PTM7950 only comes in 0.25mm:

And here on page 7.

On page 3 of this PDF specifically for PTM7950 says .25mm (which the ebuy7 link refererences), and the picture shows the material with a slightly blue-ish color (EDIT: turns out the material is the same color, just the plastic film has a blue tint):

Which leads me to believe that the product I bought from ebuy7 is the genuine one. EDIT: The aliexpress 0.2mm version is definitely performing well thermally. Will report back on 0.25mm ebuy7 version. EDIT2: the 0.25mm version performs seems to perform pretty much the same as the 0.2mm version.

However, this link says that it does indeed come in 0.2mm thickness:

aliexpress 0.2mm version (notice that the color is more gray:

ebuy 0.25mm version (notice that the color is blue-ish) EDIT: the material’s the same color, it’s just the plastic film that has a blue tint:

So perhaps both are genuine PTM7950, just different thicknesses. I can’t tell for sure, so I’m going to test the 0.25mm blue-ish version and report back. EDIT: I tested out the 0.25mm version and it seems to perform pretty much the same as the 0.2mm version. I think both are genuine per their results.

Here’s my previous post with research and findings on what the material is that led me to purchasing it:

And here’s another thread of someone asking about it:

I installed it and it performs incredibly well. Installation is very easy since it can be cut to size, but a bit tricky since both sides have a plastic sheet/film which needs to be removed from the delicate thermal pad without damaging it. It’s very thin at 0.25mm (the label on my order says 0.2mm, though I think that’s incorrect) EDIT: pretty sure the aliexpress version is 0.2mm, and the ebuy7 link is 0.25mm. Thankfully, the surface area of the CPU/GPU dies are pretty small, so a 40x80mm sheet can be used for ~7-8 applications.

I installed it three times, and each time I got better at it. Here are my installation steps and some tips.

Installation and tips

Warning: do this at your own risk!

This is what it comes in:

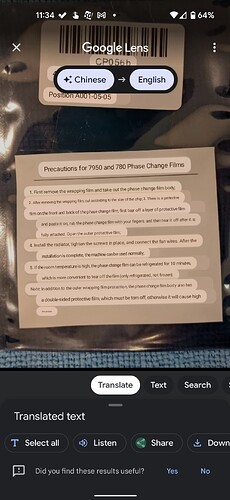

Google Lens translation:

The thermal material (bottom) and tape/adhesive (top) for removing the plastic film that’s on both sides:

Clean/prepped bare CPU/GPU dies and heatsink (using 91% isopropyl and microfiber):

Per the instructions, placing it in the fridge (not the freezer) will harden it and make it slightly easier to work with. Measure and cut to size:

Be sure to remove the plastic film before placing on the die. There’s plastic film on both sides. To remove the plastic film, you can use the included tape/adhesive like so:

But I found that simply using some packing tape that covers the entire pad worked better:

Be sure to gently “knead” the entire thermal pad into the die so that it sticks to it more than the plastic film. And I found that peeling the film from an entire edge rather than from a corner much easier:

My third, final, and cleanest application:

Important note:

After some heat cycles, the CPU/GPU dies seem to be glued/firmly stuck to the heatsink. I thought it was actually stuck, because if I pulled the heatsink directly up it’d pull the mainboard with it. I feared damaging something. However, I learned that the trick is to gently twist the fan/heatsink assembly to first “break up” the thermal material which will “unstick” it (annotated in the pic below – note: just a reference, as the pic shows the fan/heatsink assembly still plugged in and screws still screwed in). Then it can be pulled up and off.

This is how it looked after a few heat/stress cycles after my first application:

Notice how it solidifies when cool:

Benchmark and thermal numbers

I ran this on a fresh/new Windows 10 installation since that’s easy to standardize. Power plan set to High Performance. Ambient temp/AC was kept at 73F and laptop was flat on a wooden table.

- i7-1165G7

- 64GB 3200MHz RAM

- SK Hynix 2TB P31 Gold SSD

TDP

I was able to boost momentarily to a CPU package power of 60.3W like in this thread:

Cinebench R23

Single-core:

- Result: 1,528

- Sustained frequency: ~4.67GHz

- Sustained CPU package power: ~18-19W

- Max core temp: 93C

Multi-core:

- Result: 5,703 EDIT: 5,703 was the max I got. When the system has warmed up a bit, I’m getting ~5,550.

- Sustained frequency: ~3.35-3.5GHz; eyeballed average of 3.42GHz

- Sustained CPU package power: ~28W

- Eye-balled average core temp: ~78C

These results are faster than what NotebookCheck had with their unit:

Single-core: 1,507

Multi-core: 5,477

Though it does seem that if the laptop has been stressed for a long time (e.g. after several Cinebench/Prime95 runs) and the internal components are much hotter than right after booting, Cinebench multi-core results are slightly lower around 5,550 with a sustained frequency of ~3.35GHz. Or that might be when it’s plugged into and powered by my monitor. I think it’s the former rather than the latter and I’ll update here if I double-check. EDIT: I’m confirming that it’s the former.

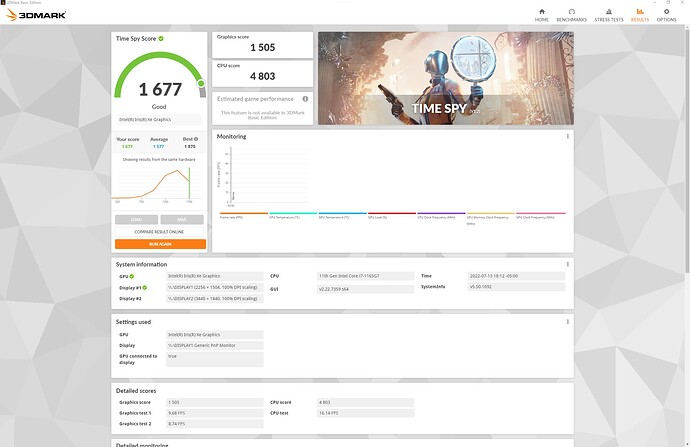

3DMark Time Spy Demo:

s-tui stress:

On Linux (Fedora 36) with EPP set to 0 (performance) and sudo thermald-set-pref set to PERFORMANCE

First paste:

Second paste:

Third paste:

It seems like results from pasting (or rather application? pad placing?) are pretty consistent as long as the entire die is covered since it’s a pad with equal thickness throughout. Kind of hard to screw up – if you do, you’ll likely know you did.

This is definitely significantly better than the results I had with Arctic Silver 5 and Arctic MX-2, though the AS5 tube’s a couple years old, and the MX-2 like..a decade old haha. I’m not sure if my prior saved results are using the same EPP/thermald values on Linux and my previous Windows installation’s TDP values were borked since the installation carried over TDP values from a prior laptop – so I won’t post those numbers. I also don’t have up to date numbers with Framework’s stock Shin-Etsu X-23-8117 thermal paste (which may be better than this, but I removed the stock paste and don’t want to order more ![]() ). So I’ve provided a bunch of up to date numbers of my laptop with PTM7950, and that can be compared with others.

). So I’ve provided a bunch of up to date numbers of my laptop with PTM7950, and that can be compared with others.

All that being said, I definitely will be keeping this in my laptop. The results are impressive (and from what I’ve read has longevity). I remembered reading these liquid metal results 1 2 – I’m going to compare against these later and report back. Got a lot of images/content saved in this post and I don’t want to lose it!

Also, since I ordered two 40x80mm sheets, still have a bunch left from the first sheet, and haven’t used the second – I can mail some out (in the US) to a few people if anyone wants to try it. And I read somewhere on the internet that it doesn’t work well for a standard CPU IHS, though PTM7950 does come in a thermal paste version (which I read anecdotally was worse than the pad/sheet).

I tried to dump most of my findings here, let me know if y’all have any questions!

EDIT 2 (vs. liquid metal and extra tips)

Here are the results compared to:

I remembered reading these liquid metal results 1 2 – I’m going to compare against these later and report back.

[1]

AIDA64 Idle:

I was seeing idle temps ~39-41C

AIDA64 CPU stress:

Ran for 10 minutes. Leveled off at ~72C

AIDA64 CPU+FPU stress:

I let the system cool for 10 minutes after CPU stress, then ran CPU+FPU. Maintained ~79-81C for the rest of the run.

[2]

EPP set to 0 / performance and thermald set to PERFORMANCE.

Left terminal:

sudo stress-ng --matrix 0 --ignite-cpu --log-brief --metrics-brief --times --tz --verify --timeout 2m

Right terminal:

watch -n 1 sensors

Around ~76C – quite impressive! This seems to perform pretty close to liquid metal.

I forgot to mention that after my first application, I did bend the clips like mentioned here (at your own risk!):

Also, thin needle nose pliers can help with removing the film: